Project Overview

Task Assigned

Challenges

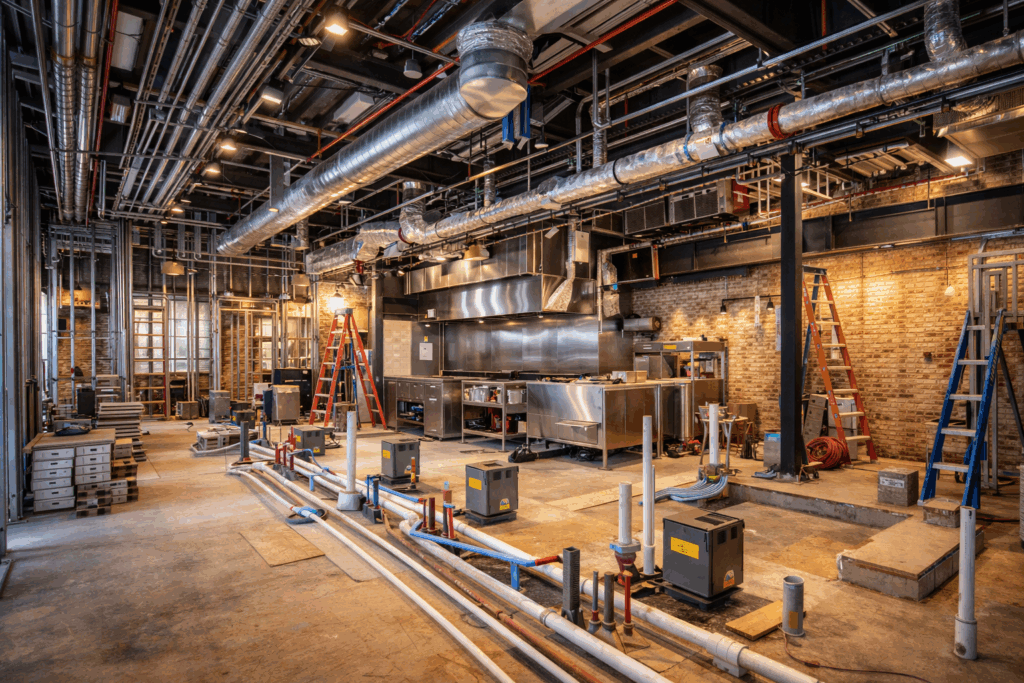

The biggest challenge stemmed from working within an existing two-story structure with fixed ceiling heights and limited ceiling plenum space. Routing ductwork and piping without altering floor levels or disrupting aesthetics required careful spatial planning.

Compounding this was the fire-rated exterior wall, which limited opportunities for venting and exhaust terminations, mainly since the restaurant was situated below a residential apartment unit, leaving no direct access to the roof for typical vent routing.

In the open bar area, the plumbing team faced difficulty venting floor sinks and fixtures due to the location and code constraints. Limited outdoor space also complicated the installation of an appropriately sized grease interceptor.

On the electrical side, integrating new HVAC units and commercial kitchen equipment into an existing and nearly maxed-out service panel required redistribution planning. Achieving a balance between aesthetic lighting design and code-compliant illumination levels was an additional layer of complexity.

Solutions

To overcome the spatial constraints, our MEP team worked closely with the architect to create a ceiling coordination strategy that minimized elevation changes. Where height adjustments were unavoidable, the team proactively identified and communicated these zones to streamline field execution.

Existing images and site measurements, supplemented with Google Street View, helped the team verify and utilize available exterior openings for ventilation and exhaust routing.

At the concept stage, the National MEP Engineers team developed alternate HVAC strategies based on the architect’s layout and existing building conditions. Early coordination helped the client understand system requirements and make informed decisions. The team also proposed strategic access panels for future HVAC maintenance, which were approved and integrated into the design.

For the bar plumbing, conventional venting wasn’t feasible due to distance and obstructions, so the team introduced air admittance valves and strategically placed short-run underground vents to remain within code. Without access to a rooftop, the team terminated vents through the side walls, away from pedestrian paths, and routed exhaust ducts through the alley side to maintain the building’s aesthetics.

Since exterior equipment was restricted in the urban setting, the team specified compact, in-series hydro-mechanical grease interceptors, sized based on calculated FOG loads, that could fit within tight underground spaces.

To address the electrical load challenge, the team proposed a new panel and load redistribution and recommended switching to gas-powered heating equipment to alleviate the panel’s additional electrical demand. For lighting calculations, AGI32 was used, which informed the selection of fixtures and led to the implementation of light controls for intuitive lighting management that satisfied both aesthetic and energy code requirements.

Client Impact

National MEP Engineers delivered a fully integrated and code-compliant MEP solution tailored to the unique conditions of the Flying Monk renovation. Their creative problem-solving approach, encompassing venting, equipment placement, and load management, enabled the client to preserve architectural intent while achieving energy compliance and operational efficiency. The result was a successful transformation of a retail space into a modern dining environment, completed on time and with minimal design conflicts—reinforcing National MEP’s reputation as a reliable partner for adaptive reuse and complex renovations.